From a manufacturing point of view, silver oxide and silver nitrate are the same, since silver oxide is a first stable thermal derivative of silver nitrate.

In addition, an expensive finely milled vanadium source is required for this process. This blending step is critical because it is important to minimize diffusion distances in a solid-state reaction by ensuring that the components are distributed evenly with maximum physical contact. This blending operation needs more energy than a simple agitation type blending process and a ball-milling or vibro-energy milling procedure is required for appropriate mixing. This blend is calcined, typically in ambient atmosphere, for an extended period, (can be +24 hours at temperature excluding long ramp times) at a temperature near the liquidus phase boundary in the SVO contained phase diagram. The product of this reaction is a crystalline, dark purple-black very hard agglomerate body. At this stage, the quite large, plate –like crystals are usually visibly larger on the surface of the mass than the interior. This hard crystalline mass requires extensive mechanical breakdown, for example jaw crushing, and a further period of grinding (ball-milling or vibro-milling) and screening to a very specific particle size distribution. The calcination process is repeated a second time, for a similarly extended period, and the subsequent hard agglomerated mass of large crystals is again subjected to an extensive crushing, grinding and screening operation to yield a specific particle size distribution. It is also necessary to carefully adjust the ratio of the primary components so that a phase –pure SVO is obtained. An optional exercise is the annealing of the crystals to possibly erase damage to the crystals created during final grinding, although this has not been shown to impart any beneficial characteristics.

This traditional process has many drawbacks. The process is time-consuming and expensive. A premium price is paid for a suitably pure and finely milled Vanadium source. Silver nitrate, if used is, typically, a coarsely crystalline material and requires extra special care in the blending process. The blending processes necessitate extreme operator protection from the very toxic Vanadium dust generated during the many crushing, grinding and screening processes. This requires the installation of expensive, permitted, dust collection systems and a plan for the disposition of the hazardous waste streams generated by this process.

Clearly, this is a time consuming, expensive process with considerable hazardous exposure risk to manufacturing operators. It relies very heavily on the efficiency of the multiple blending, calcination and intermediate grinding and screening steps.

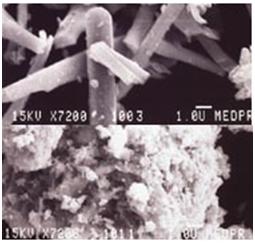

In view of these disadvantages, Lorad scientists have developed a new process for manufacturing high quality silver vanadium oxide. This new process eliminates the blending process. It further eliminates all initial and intermediate crushing, grinding and screening processes. It requires only one calcination step, of very limited duration (much shorter times than current processes), to yield a fully developed, highly crystalline SVO powder with excellent electrical characteristics. It has also been demonstrated that under certain conditions a very high degree of crystalline orientation can be introduced. The product is a needle/sheet-like, light, very loosely agglomerated material. It does not require any mechanical force to free it from the calcination container, and can be used ‘as-is’ for blending with the components necessary to press the cathode pellet. Clearly, this process is considerably less costly in terms of manufacturing facilities required, energy costs, labor and raw materials. The requirement for an expensively milled Vanadium source is reduced, and there is a greatly reduced risk of employee exposure to toxic vanadium chemicals.

A further advantage of this process is the ease with which the material composition may be varied for potential optimization and modification of the discharge curve characteristics. Work is in progress to develop procedures for the modification and control of micro structural characteristics.

This process is not restricted by current patents, and material is currently available in initial commercial quantities.

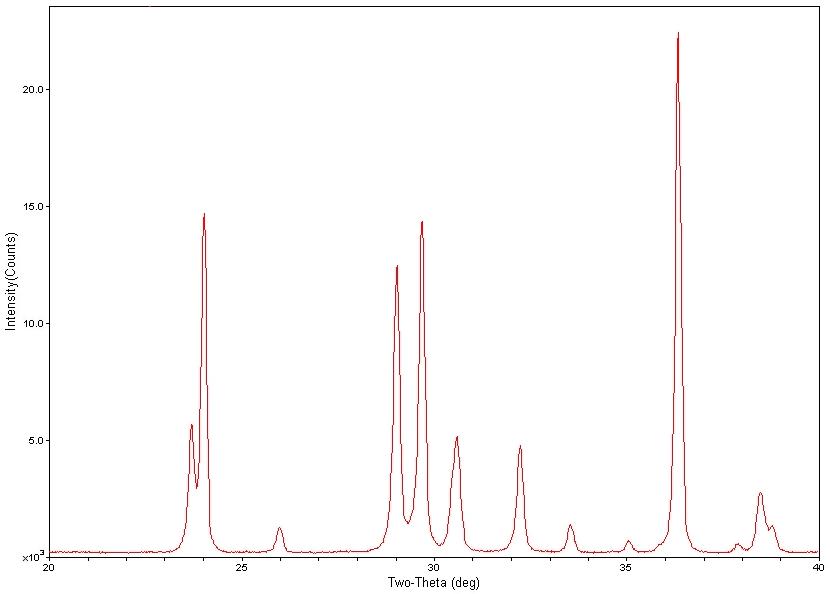

Above, is shown a typical x-ray diffraction trace of a phase-pure silver vanadium oxide.

The top part of the above micrograph shows a typical SVO microstructure as advertised by Medtronic. The needle-like morphology associated with SVO is clearly visible, but the morphology is markedly different from the Lorad material. The lower part of the micrograph is reported by Medtronic to be a typical synthesized SVO microstructure.