Gadolinium Aluminate, GdAlO3, has potential applications as a co-dopant for ferroelectric materials, phosphors, scintillators, neutron absorption, and oxygen ionic conductors.

This material is typically synthesized by a solid-state reaction of gadolinia and alumina powders, which involve extensive mechanical mixing and lengthy heat treatments at 1,500ºC to produce coarse and highly sintered particles.

This process was inefficient in both production time and cost. After being engaged to develop a more efficient procedure for this material, Lorad conducted a research and development program that has yielded a novel combustion synthesis procedure to manufacture phase-pure Gadolinium Aluminate nano-powder.

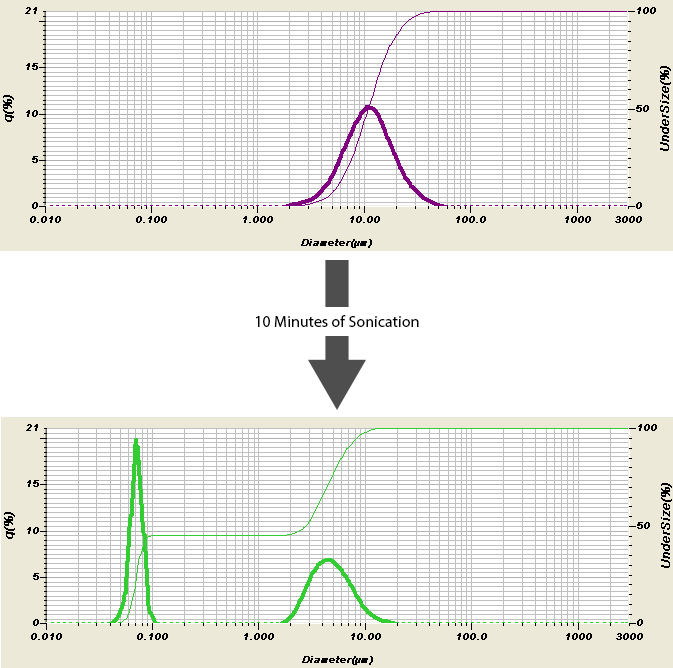

After subjecting the precursor materials to our combustion synthesis process the agglomerated particles were measured to have an initial D50 of approximately 10 microns. At this stage, the material consists of soft agglomerates. To break up the agglomerates, we subjected the powder to ten minutes of sonication. After this short sonication period, 45% of the particles measured by our Horiba Particle Size Analyzer were found to be smaller than 100 nanometers. Additional sonication continued to break up agglomerates and raise the percentage of nano-sized particles.

Particle size analysis after 10 minutes of sonication

Particle size analysis after 10 minutes of sonication

Our Gadolinium Aluminate, with the particle size distribution described above and a purity of 99.9%, will provide increased efficiency and additional cost savings for any company, university, or other organization developing or manufacturing any of the aforementioned applications.

You can inquire about Gadolinium Aluminate, directly on our catalog page, through our online inquiry form, or by emailing us directly at sales@loradchemical.com. Additionally, if you are looking for doped variation of Gadolinium Aluminate, our team can custom synthesize a wide variety of doped products.