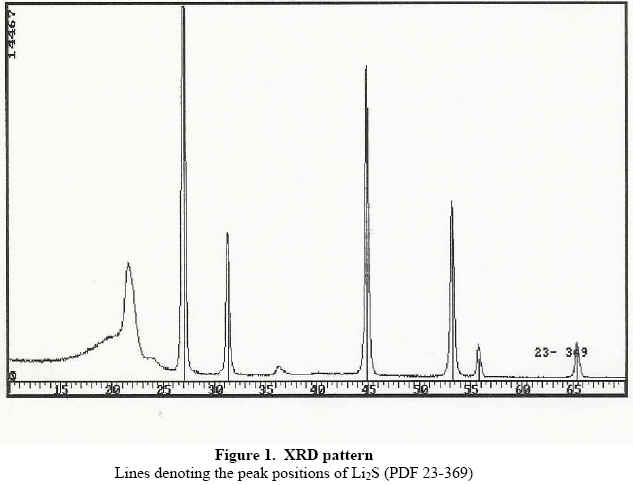

Lorad Chemical is pleased to annouced that as part of our ongoing development program for Lithium Sulfide, we have deployed a novel improvement for the manufacturing of Lithium Sulfide powder that will now allow us to offer large multi-kilogram quantities with improved delivery dates. Shown below is a typical x-ray diffraction pattern for our Lithium Sulfide powder. It should be noted that the broad band at low 2theta, and the peaks at approximately 21.5, 24, and 36.5 are due to the polyethylene enclosure protecting the Lithium Sulfide from atmospheric degradation during the x-ray diffraction process.

To ensure that our customers receieve the high-purity battery grade product that we produce, we take several steps during the final preparation of Lithium Sulfide to protect it from atmospheric degradation. Our powder is packaged under dry inert gas into glass containers that are sealed and placed in metal cans, which are flooded with inert gas and sealed with hydrophobic PTFE closures. Please inquire for pricing and availability.